Summary:

This machine is designed to remove plastic shell products and identify finished items with flawed appearances. Equipped with high-resolution Ethernet industrial cameras and an advanced operating system, it conducts meticulous image-based inspections, individually eliminating defective items. This technology minimizes human misjudgment, enhancing detection stability and efficiency in the realm of Film Capacitor Appearance Inspection.

Features:

1. Automatic Feeding: Utilizes a vibration plate for seamless feeding.

2. Automated Material Transfer: Facilitates automatic in-channel positioning.

3. Full-Angle Coverage:Employs 7 cameras for comprehensive angle coverage.

4. Automated Detection:The system automatically compares and identifies collected images.

5. Auto Elimination: Defective items are identified and eliminated by the system.

6. Auto Collection:The system categorizes and collects approved products based on identification results.

7. User-Friendly Operation:Parameter setup is effortless via the computer interface.

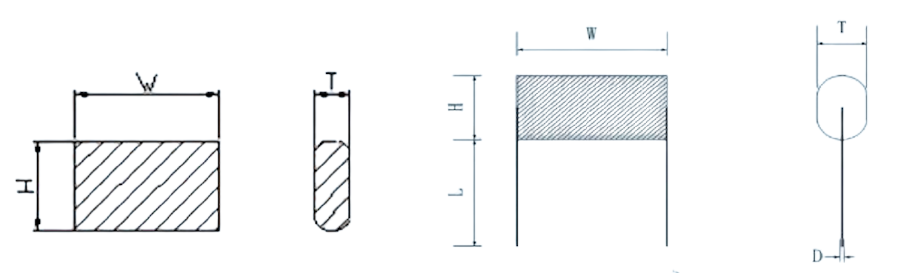

Product size range

| Side length | mm |

|---|---|

| W | 13.0—32.0 |

| H | 9.0—25.0 |

| T | 4.0-13.0 |

Specifications

| name | value |

|---|---|

| Machine capacity | 70-90 PCS/min (depending on product size) |

| Input power | 220VAC, 50/60Hz single phase, 2KVA |

| Weight | 650Kg |

| Size | 3000L X 1600W X 1850H (mm) |

Chinese

Chinese