1. Summary

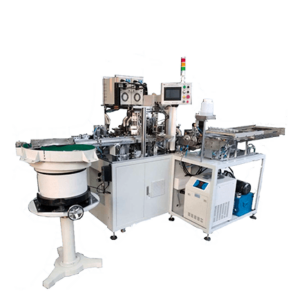

This machine is designed for the automated production of metal film capacitors, integrating five processes: forming, welding, plug shell insertion, dispensing, and publishing. It significantly reduces the need for manual operation, making it suitable for X2 capacitors.

2. Features:

1. High stability: Innovative design and intelligent integration ensure high efficiency and stability of the equipment.

2. Energy savings: Continuous operation in multiple steps eliminates idle handling, leading to energy conservation.

3. Reduced labor: Integration of five independent processes substantially reduces the need for manual intervention, resulting in significant labor cost savings.

4. Improved quality: Minimization of handling and blanking processes enhances product quality by reducing bending and wear.

5. Intelligent operation: Advanced touch screen and PLC control, along with analytical technology, enable effective monitoring of automated equipment operation.

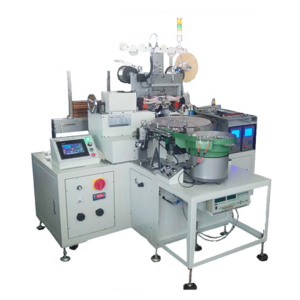

| The machine is suitable for sub-prime size range | |

|---|---|

| W | 26.0-52.0mm |

| H | 10.0-50.0mm |

| T | 10.0-42.0mm |

| L | 30.0-45.0mm |

| D | 0.8-1.2mm |

| Efficiency | |

| Two pins welding | 20pcs / min |

| Four pins welding | 12pcs / min |

| Machine main parameters | |

| Host size | 2600 X 1700 X 1800 (length X depth X height) |

| Weight | About 700Kg |

| Power source | 220V 8KW |

Chinese

Chinese