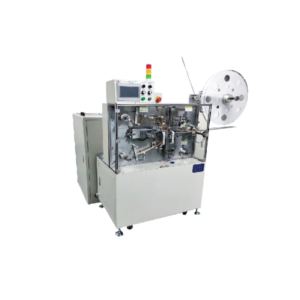

1. Summary:

The machine’s role in the sub-prime metalized film capacitors spray process is to facilitate the packaging with pressure-sensitive adhesive tape. This process prevents sub-prime capacitance from experiencing short-circuits or damage during spraying. After the spray, the protective tape can be easily removed without causing harm to the sub-prime itself. This approach saves both time and effort while yielding economic benefits.

2. Features:

1. Cutting Mode: The machine offers a default mode for the next lath material, suitable for square sprayed gold plates. Additionally, users have the option to select the disk-shaped cutting mode.

2.Parcel: By center-pressing the bag, the machine ensures a comprehensive and tightly packed core. Afterward, the outer core package is straightened into a straight-line lath shape, ensuring no gaps between the core components.

3. Easy Operation:The machine features a touchscreen interface combined with conventional buttons, allowing for smooth and effortless operation.

4. Easy Adjustment: The placement of four plate tapes on the panels is compact and user-friendly, facilitating easy adjustments.

5. Space Saving: The design of the machine is aimed at effectively saving space.

| Applicable product size range | ||

|---|---|---|

| Dimension | D (Diameter) | W (Length) |

| Size (mm) | 20.0-40.0 | 25.0-70.0 |

| Specifications | |

|---|---|

| Packing capacity | 2,000 pcs/hour (dependent on different element type) |

| Packing mode | Pressure sensitive tape full surround slat cutting |

| Management ability | Each operator could manage 5 machines |

| Raw tape plate size | Outside diameter: max. 260mm, Inside diameter: 76mm |

| Finished products | 450mmX500mm. Square tray |

| Power | AC 220V, 50/60Hz, 3KVA |

| Weight | 600 kg |

| Machine dimensions | 1600L x 1300W x 1700H (mm) |

Chinese

Chinese