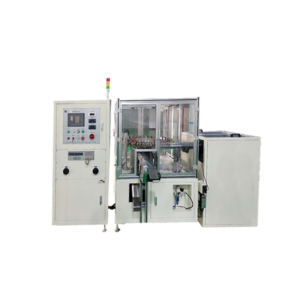

Clearing process equipment includes machines like FNC1 (36 station), FND1 (48 station), FNW1 (36 station horizontal), FNW2 (30 station horizontal), FNB1 (24 station big element), FNB2 (auto capacitor), and FNB3 (16 station vertical) for removing and energizing metallized film capacitor cores, addressing short circuits caused during manufacturing through voltage application.

Clearing Process Equipment: A range of machines, such as FNC1, FND1, FNW1, FNW2, FNB1, FNB2, and FNB3, is dedicated to removing and energizing metallized film capacitor cores, addressing manufacturing-induced short circuits through voltage application. These machines accommodate various sizes and enhance pressure resistance. Film Capacitors: 1. Summary: This equipment primarily serves to remove and energize metallized film capacitor cores, eliminating short circuits resulting from manufacturing processes such as thin film evaporation, coiling, hot pressing, and spray welding. Voltage application facilitates the cleaning process. 2. Features: 1) Removal of large-sized capacitors. 2) Handling of capacitors with large capacity. 3) Thorough removal and enhancement of pressure resistance. Content optimized and summarized in a single sentence.

Chinese

Chinese