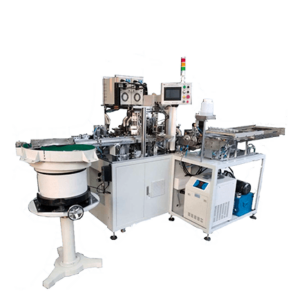

Summary: Explore an automated solution designed for metallized film capacitor manufacturing, seamlessly integrating empowering, welding, shell insertion, dispensing, and typesetting processes. Tailored for medium and large box-type capacitors, this machine optimizes assembly, welding, and encapsulation through exceptional automation. Anticipate flawless welding outcomes, consistent potting quality, and remarkable operational efficiency.

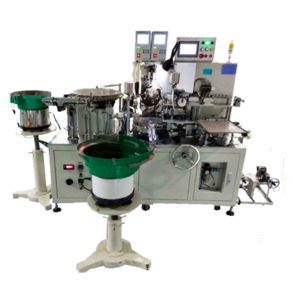

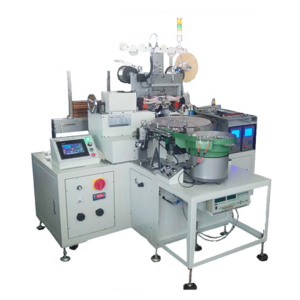

Summary: Explore an automated solution designed for metallized film capacitor manufacturing, seamlessly integrating empowering, welding, shell insertion, dispensing, and typesetting processes. Tailored for medium and large box-type capacitors, this machine optimizes assembly, welding, and encapsulation through exceptional automation. Anticipate flawless welding outcomes, consistent potting quality, and remarkable operational efficiency. Key Features of the Pin Welding Assembly Machine: Revolutionize your production line with this cutting-edge equipment, accommodating multi-pin products. It handles lead pin forming, cutting, core welding, glue filling, assembly, sealing, and product collection. With the flexibility to handle two-pin, four-pin, and multi-pin configurations, it also includes lead pin bending in both directions. Welding Assembly Process Equipment: - Model 20—FHGP-C1: Clearing-Welding Assembly Machine - Model 21—FHGH-C1: Single Oven Clearing-Welding Assembly Machine - Model 22—HGP-C2: Welding Assembly Machine - Model 23—HGP-D1: Big Element Welding Assembly Machine Experience unparalleled efficiency as this comprehensive welding assembly equipment effortlessly manages forming, welding, shell insertion, dispensing, and publishing tasks. Enhance production efficiency while minimizing manual intervention. Tailored for automated metal film capacitor manufacturing, this solution caters to up to 12 capacitors, exemplifying cost-effective innovation.

Chinese

Chinese