BGH2 High speed masking machine Summary:

The role of machines in the sub-prime metalized film capacitors spray process has evolved. Previously, the machines were used to pack the capacitors with pressure-sensitive adhesive tape to prevent sub-prime short-circuits or damage due to spray. The protective tape could be easily removed after spraying without harming the capacitor itself, leading to time and effort savings and economic benefits.

BGH2 High speed masking machine Features:

1. Ω Type Package: Capacitors are tightly wrapped, effectively saving spray material.

2. High Efficiency: Packing speed is faster than BGC1, approximately twice as fast.

3. Low Noise: Mechanism employs sine wave mechanical transmission for reduced noise.

4. Quick Operation and Specification Adjustments: Adjustments can be made rapidly and easily.

5. Latest Update: Incorporates touch screen and PLC control for enhanced convenience.

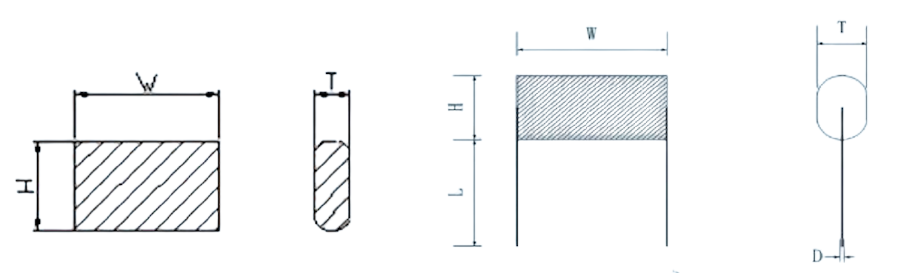

BGH2 High speed masking machine Applicable sub-prime machine body size range

| Side length | Standard vibration plate mm |

|---|---|

| W (Long) | 7.5——25 |

| H (High) | 8.0-17 |

| T (Thick) | 2.5-8 |

BGH2 High speed masking machine Specifications

| name | value |

|---|---|

| Packing capacity | 8,000-10,000 pcs/hour (depend on different element type) |

| Packing mode | Ω-type packing with tape |

| Management ability | Bach operator could manage 5 machines |

| Raw tape plate size | Outside diameter: max. 260mm, Inside diameter: 76mm |

| Pinished products | Outside diameter: max. 650mn, Inside diameter: 76mm |

| Power | AC 220V, 50/60HZ , 2KVA |

| Weight | 250 KG |

| Machine dimensions: | 1300LX1050WX1650H (mm) |

Chinese

Chinese