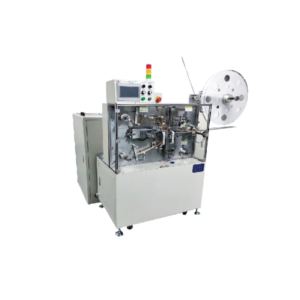

1. Summary:

The machine plays a crucial role in the sub-prime metalized film capacitors spray process. Its primary function is to ensure proper packaging using pressure-sensitive adhesive tape. This process prevents any potential short-circuits or damage to the sub-prime capacitors caused by the spraying process. Importantly, the protective tape can be easily removed after spraying without harming the sub-prime itself. This streamlined approach not only saves time and effort but also contributes to positive economic outcomes.

2. Features:

1. Introduced in January 2012:This machine was introduced to the market with a focus on catering to smaller capacitor sub-prime packages, some as thin as 1.2mm. By enhancing the efficiency of the spraying process, particularly for closer and thicker package trays, it contributes to time savings, especially for ultra-small capacitor types.

2. Enhanced Packing Speed: This machine boasts a faster packing speed compared to BGS1, capable of packaging up to 8,000 sub-primes per hour.

3. Efficient Resource Allocation:The machine design is geared towards saving manpower, allowing each operator to effectively manage five machines.

4. Quick and Easy Adjustments:The machine enables swift and hassle-free operation and specification adjustments.

Side lengthStandard vibration plate mm

| Applicable sub-prime machine body size range | |

|---|---|

| W (Long) | 5.0-10.0 |

| H (High) | 3.5-6.0 |

| T (Thick) | 12-10 |

| Specifications | ||

|---|---|---|

| Packing capacity | 8,000 pcs/hour (depend on different element type) | |

| Packing mode | Pressure sensitive tape chain packaging T>2mm may | |

| Management ability | Each operator could manage 5 machines | |

| Raw tape plate size | Outside diameter: max. 260mm, Inside diameter: 76mm | |

| Finished products | Outside diameter: max. 400mm, Inside diameter: 76mm | |

| Power | AC 220V, 50/60HZ , 2KVA | |

| Weight | 250KG | |

| Machine dimensions | 1300LX1050WX1650H (mm) | |

Chinese

Chinese