Summary:

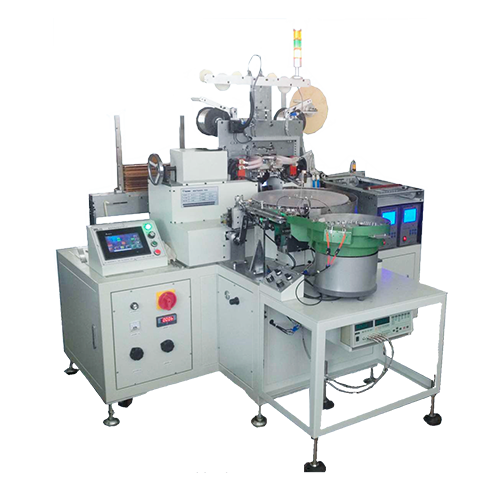

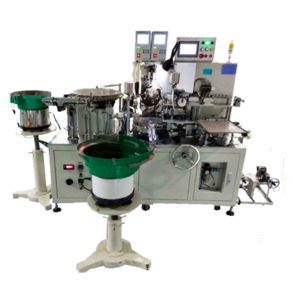

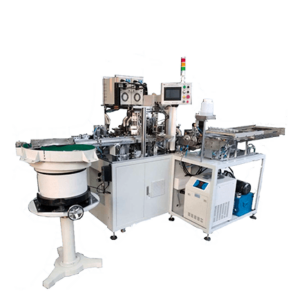

This machine integrates two or three types of equipment to achieve energization, welding, assembly, and silicone oil coating processes. It combines four distinct steps into a single unit, greatly reducing manual intervention and production costs, while enhancing product qualification rates and efficiency.

Features:

1. High Stability: Merging expertise and innovative design to seamlessly blend efficiency and stability in the equipment.

2. Energy Efficiency: Continuous operation over four steps eliminates idle periods, resulting in enhanced energy savings.

3. Reduced Labor: Integration of four distinct processes significantly reduces required personnel, leading to substantial annual labor cost savings.

4. Improved Quality: Minimized handling and blanking processes ensure reduced wear and curved leg issues, resulting in a marked quality improvement.

5. Intelligent Operation: Utilizing advanced touch screens, PLC control system technology, and analytical capabilities for effective and automated equipment monitoring.

6. Capacitance Detection: Includes pre-sorting and removal of defective materials.

7. Flexible Layout: Aluminum square tube arrangement can be adjusted as per specific requirements.

Lorem ipsum dolor sit amet...

| Specifications | |

|---|---|

| Main Parameters | |

| Host Size | 1830 x 1760 x 1710 (Length x Depth x Height) |

| Weight | About 1000 Kg |

| Power Source | 220V 8KW |

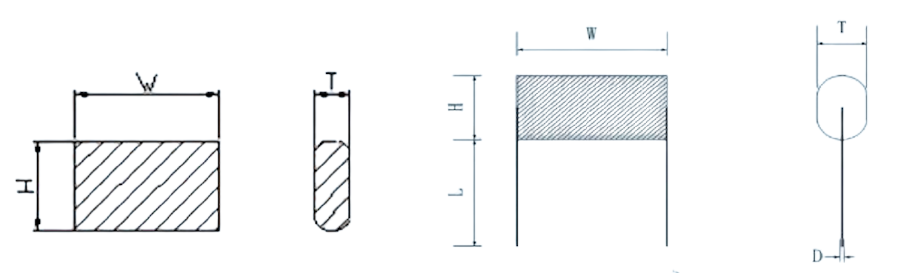

| Applicable Size Range | mm |

|---|---|

| W | 5.0-27.5 |

| H | 4.0-17 |

| T | 2.0-10 |

| L | 20-35 |

| D | 0.5-1.0 |

Chinese

Chinese