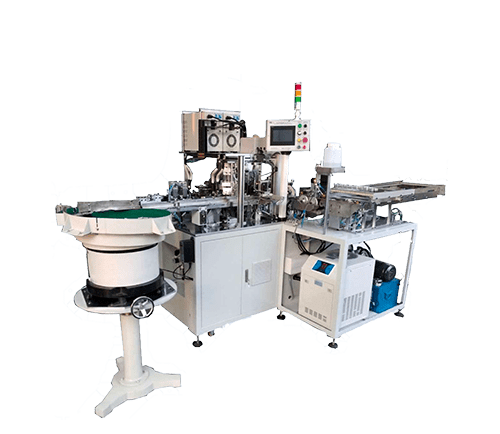

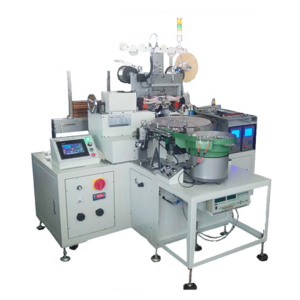

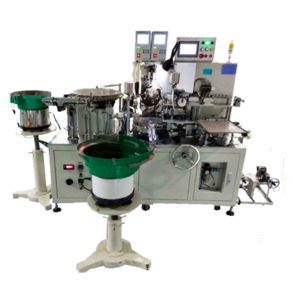

FHP-D1 Big element clearing-welding-tapping machine Summary:

This machine performs welding and manual handling using three distinct types of machinery. It applies silicone oil, automatically frames components, and consolidates four separate processes into a single unit. This integration significantly reduces the need for operators and production costs, while also aiming to enhance product qualification rates and production efficiency.

FHP-D1 Big element clearing-welding-tapping machine Features:

1. Efficient and Stable:Combining ingenuity with innovative design results in equipment that achieves a harmonious balance of high efficiency and stability.

2. Energy Saving:By allowing four processes to run continuously, the equipment eliminates idle speed operations during transportation, leading to energy savings.

3. Labor Reduction: The high integration of four independent processes exponentially reduces the required number of personnel for equipment operation, resulting in substantial annual labor cost savings.

4. Enhanced Quality: By minimizing handling or blanking processes, the quality of the final product is significantly improved, mitigating defects, wear, and similar issues.

5. Intelligent Operation: Cutting-edge touch screen and PLC control system technology, combined with analytical techniques, enable the automatic operation of the equipment while providing effective monitoring.

6. Capacitor Wire Solder Joint Detection:Automatic identification and removal of faulty products through the detection of capacitor wire solder joints.

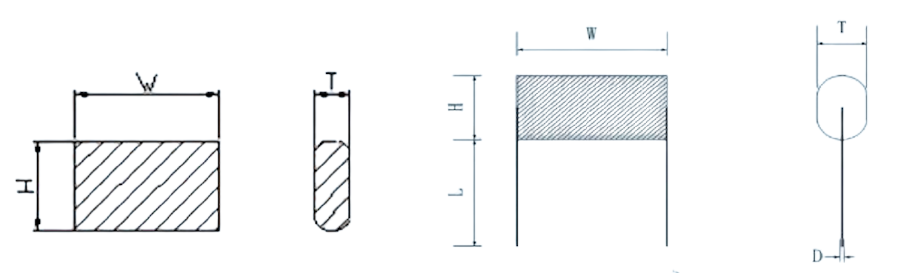

Machine applicable prime size range

| Side | Length(mm) |

|---|---|

| W | 27.5—52.0 |

| H | 15.0—45.0 |

| T | 7.0—32.0 |

| L | 25.0—35.0 |

| D | 0.8—1.2 |

Main parameters of the machine

| name | value |

|---|---|

| Host size | 3400×1850×2150((LxWxH) |

| WEIGTH | about 1000Kg |

| POWER | 220V 8KW |

| Welding power supply | DC inverter |

| Productivity | 30-40pcs/min |

Chinese

Chinese