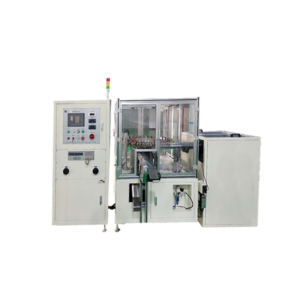

1. Summary:

This machine is primarily designed to clean the elements of metallized film capacitor cleaning devices. Its primary function is to remove short circuits caused by film evaporation, coiling, hot pressing, and spray welding during the manufacturing process. The cleaning process involves applying a voltage to the capacitor to clear any potential issues.

2. Features:

1) Large-sized Capacitor Cleaning: Capable of cleaning large-sized capacitors.

2) High Capacity Cleaning: Can effectively clean capacitors with large capacities.

3) Thorough Cleaning: Ensures a comprehensive cleaning process to enhance product pressure performance.

4) Polarity Clearance: Can achieve positive and negative clearance, resulting in more thorough self-healing capabilities.

5) Automated Detection and Sorting: Automatically detects and sorts capacities and losses.

6) Flexible Power Control: Power settings can be adjusted using current-limiting resistance, allowing for switching between different capacity power requirements.

7) Enhanced Safety: Features a complete machine cover shell for improved safety during operation.

8) Independent Power Supplies: Equipped with three independent power supplies that individually control power voltage, ensuring accuracy and stability.

9) Leakage Current Monitoring: Capable of monitoring leakage current during the charging process.

10) Capacity Record Keeping: Allows for reading and archiving of product capacity and loss values for each batch.

| Product size range | |

|---|---|

| W: | 20~60mm |

| H: | 30~70mm |

| T: | 15~40mm |

Chinese

Chinese