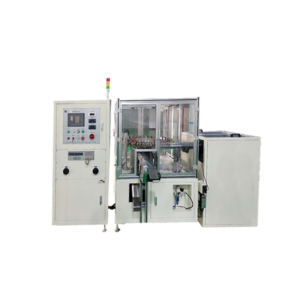

1. Summary:

This machine is primarily designed for clearing the elements of metallized film capacitors. Its function is to eliminate short circuits caused by film evaporation, coiling, hot pressing, and spray welding during the manufacturing process. The clearance is achieved by applying voltage to the capacitor.

2. Features:

1) Capable of removing round capacitors with large diameter and height.

2) Efficient removal of large capacitors with servo screw loading and unloading, ensuring higher accuracy.

3) Effective voltage control: The machine employs a DC switching power supply, which offers more precise voltage control compared to traditional transformer rectifiers. For products with different voltage requirements, the machine adopts a three-block resistance system to effectively reduce the impact on capacitance empowerment.

4) Enhanced arc suppression: DC power supply replaces AC power supply. The electrode in contact with capacitance at each station is isolated by a transition electrode, and the discharge station is isolated by high-voltage vacuum relay to effectively prevent capacitance-related issues.

| Product size range | |

|---|---|

| Φ(diameter) | 30~136mm |

| H (height) | 26~150mm |

| Machine parameters | |

| Input power | single phase 220VAC 50Hz |

| Rated power | 7KVA |

| Productivity | 1-10pcs/min |

| Machine size | 2870 (L) X 3000 (W) X 2050 (H) |

Chinese

Chinese