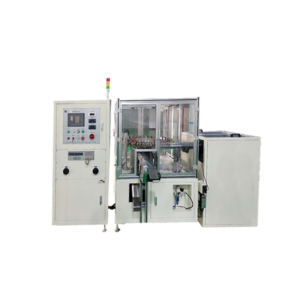

Summary:

This machine is primarily designed for removing and energizing metallized film capacitor cores. Its primary function is to eliminate short circuits caused by thin film evaporation, coiling, hot pressing, and spray welding during the manufacturing process. The cleaning process is achieved by applying voltage to the capacitor.

Features:

1) Vibration plate and belt linear combination for efficient operation.

2) Electrical settings ensure that the element remains undamaged during production, and the Dissipation Factor (DF) remains unchanged without increase.

3) Simultaneous multi-stage voltage processing for time-saving efficiency.

4) Adjustable voltage and speed settings based on process requirements.

5) Utilizes a splitter transmission mechanism for enhanced stability, reliability, and prolonged operational life.

6) Offers comprehensive forward and reverse clearance for thorough cleaning.

| Product size range | |

|---|---|

| W | 7.5~27.5mm |

| H | 5.0~20mm |

| T | 2.5~15mm |

Chinese

Chinese