Summary:

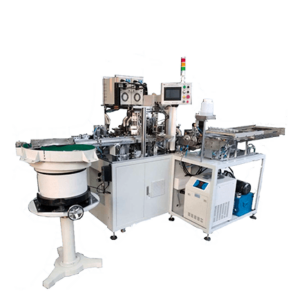

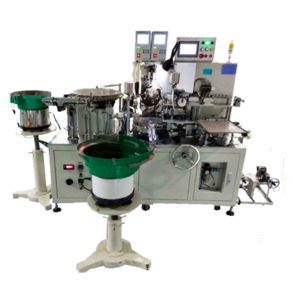

This machine automates the production of metallized film bulk capacitors by integrating welding, shell insertion, dispensing, and typesetting processes. It significantly reduces labor through single equipment operation and is suitable for molded case capacitors.

Features:

1. Efficient and Stable: Combining wisdom and innovative design to achieve a perfect blend of high efficiency and stability in the equipment.

2. Energy Saving: Multiple continuous processes eliminate idle equipment handling, resulting in higher energy savings.

3. Labor Reduction: Highly integrated with four independent processes, leading to substantial annual labor cost savings.

4. Improved Quality: Reduction of handling or blanking processes prevents bending of feet, wear, and other losses, resulting in significantly enhanced product quality.

5. Operational Intelligence: Utilizing advanced touch screen and PLC control technology along with analysis capabilities for effective monitoring of automatic equipment operation.

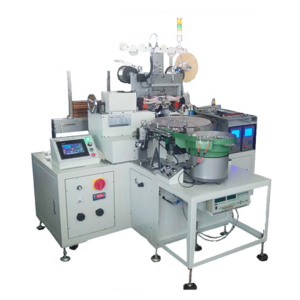

| Machine applicable prime size range | |

|---|---|

| W | 27.5~37.5mm |

| L | 20.0~30.0mm |

| H | 20.0~36.0mm |

| T | 15.0~25.0mm |

| D | 0.8~1.0mm |

| Main parameters of the machine | |

| Host size | 2600x1700x1800 (LxWxH) |

| WEIGTH | About 700Kg |

| POWER | 220V 8KW |

| Welding power supply | DC inverter |

| Productivity | 40~60 pcs/min |

Chinese

Chinese